Data center cooling, due to its variability and great energy saving potential, has become the focus of Application A: XFlexTM Mounted on Side of Data Center attention recently and in the future. Because of this, Qe has launched the energy efficient XFlexTM series, a modularized evaporative cooling system to meet the energy-saving requirements of the data center.

Qe XFlexTM adopts advanced indirect evaporative cooling technology which is specially designed for high efficient cooling in the data center. The principle is that the wet bulb temp is lower than the dry bulb temp to increase the time of free cooling. More than 60% of the energy consumption of the air conditioning can be saved by a combination of air-side efficient heat exchange cooling and evaporative cooling most of the year.

XFlexTM Operation Modes of Cooling System

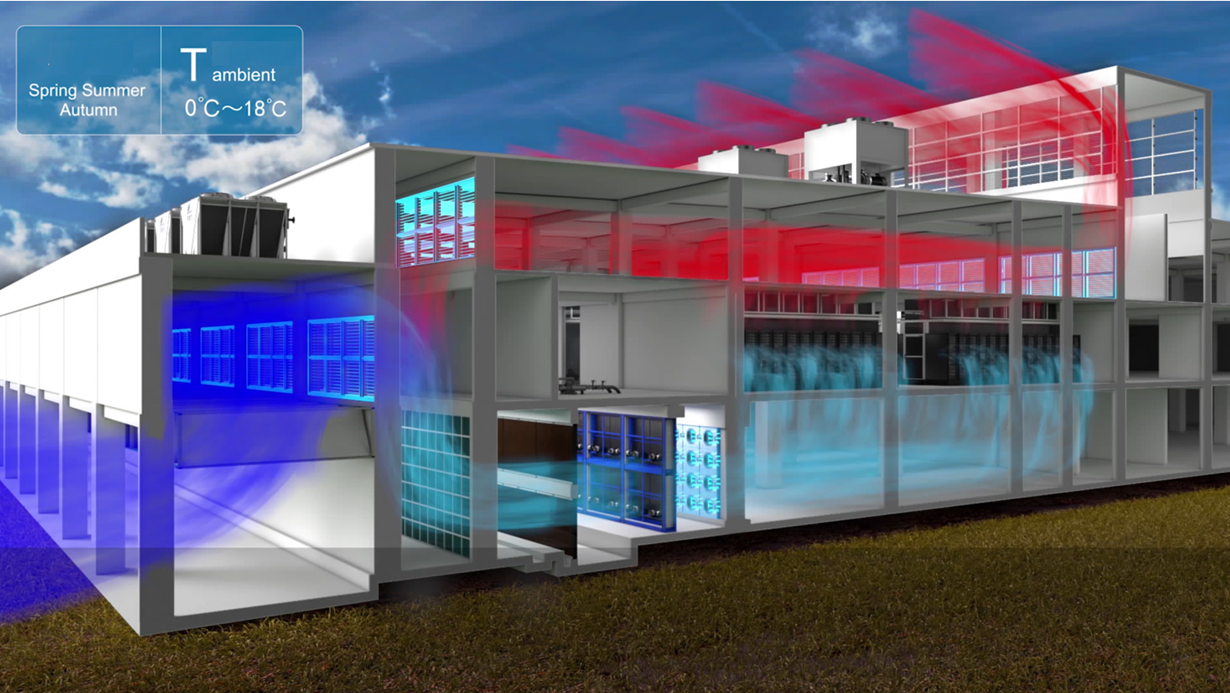

The XflexTM cooling system has three main operating modes. Air-to-air heat exchange dry mode, indirect evaporative heat exchange wet mode and mixed mode of evaporative cooling & DX/CW.

XFlexTM How to Realise High Efficiency & Energy Saving

The XFlexTM modular evaporative cooling system provides significant energy savings when deployed. This can be seen in the Northern region where is exceeds 6000hr of operation.

Compared with traditional air conditioning systems and chilled water free cooling systems, XFlexTM can save more than 60% energy, effectively reducing power consumption and providing a greener and lower-carbon data centre.

Compared with direct air-side free cooling, XFlexTM does have a similar energy efficiency. It isolates the air between indoor and outdoor effectively and reduces indoor pollution but has a lower total operating cost.

Annual PUE for Different Air Conditioning Solutions

| Power Consumption / 10,000kWh | Cost / 10,000 $ | Water Consumption / 10,000 Tons | Water Cost / 10,000 $ | |

| Traditional Air Conditioner Solutions | 5782 | 690 | 0 | 0 |

| Chilled Water Air Conditioner Solutions | 5256 | 627 | 31 | 47 |

| Free Fooling Solutions for Chilled Water | 3154 | 377 | 27 | 40 |

| Direct Evaporative Cooling Solutions* | 1156 | 138 | 25 | 37 |

| Direct Evaporative Cooling Solutions** | 841 | 100 | 18 | 26 |

| Indirect Evaporative Cooling Solutions | 1051 | 12 | 9 | 14 |

The operation costs of different cooling solutions in Beijing area, 10,000m2 data centre, the load of 12000kWfor IT equipment.

*The air cleanliness and air contaminant content exceed the standard for 12% of he time and free cooling needs to be turned off

**Clean air, no corrosive gas, small change on humidity in the four seasons

Modular Design & High Adaptability

- Realise for 100-400kW cooling systems through basic modules

- Various combined installation methods, factory prefabrication, easy to install

- Adapt to cold or hot aisle application

High Availability

- Strict factory testing and verification, integrated products and standard modules

- Ensure that the installed products are consistent before delivery, high reliability

- Easy maintenance design, reliable core components

Efficient Evaporative Cooling

- Indirect evaporative cooling, high efficiency and safe

- Free cooling mainly and mechanical cooling for top-up

- Switch between different modes intelligently

Patented Heat Exchange Core

- Patented polymer heat exchange core with excellent heat exchange performance

- Corrosion protection: resistant to acidic and alkaline liquid and corrosive gases

- Adapt to harsh environment: Resistant to high temperature, low temperature and high and low temperature shocks

- Light weight

- Low requirements on water quality

Model XF260C Module

- Power Supply – 380V / 3Ph / 50Hz

- Cooling Capacity – 260 kW per module

- Indoor Fan Airflow m3/h – 61,000

- Outdoor Fan Airflow m3/h – 72,000

- Dimensions:

- Width (mm) – 7300

- Depth (mm) – 3000

- Height (mm) – 5396

Model XF200 Module

- Power Supply – 380V / 3Ph / 50Hz

- Cooling Capacity – 200 kW per module

- Indoor Fan Airflow m3/h – 47,000

- Outdoor Fan Airflow m3/h – 54,000

- Dimensions:

- Width (mm) – 6058

- Depth (mm) – 3000

- Height (mm) – 5396

EVO intelligent controller

- 7-inch, 800×480 dot matrix true color touch screen

- Temperature and humidity curves

- Graphical display of device running status

- Multi-level password protection

- Able to connect multiple temperature & humidity sensors and detect the temperature & humidity of the inlet/outlet air of racks

- Control mode selected according to the rack cooling demand, precise air supply to realize energy saving

- RS485 interface as standard

- Optional SNMP and TCP/IP interface

- Multiple history alarms, expanded storage of history alarms is provided

- The running data stored every 60 seconds into a rolling log.

- The relevant data can be read directly via Building Management Systems

- Team Work Function to group multiple units easily

- Selective area temperature control

- Shared temperature and humidity setting

- Team work mode: demand management, trend management, rotation and standby (lead/lag), realising adaptive energy saving

EC fan

- Saving 20%~30% energy compared to traditional AC motor

- Soft-startup function, low startup current

- Adjust rotary speed automatically according to cooling requirements and airflow pressure, and provide airflow as required

- N+1 redundant configuration of fans, ensure the airflow in case of any fan fault

- Easy-maintenance design

Inverter Drive Compressors

- Variable capacity range between 20% and 100%

- Optimum Efficiency especially at part load and mixed mode

- Soft Start providing smoother power system loading

- Precision control and timely reaction to heat load changes

- Reduction in stop start cycles reducing power consumption and increasing life cycle

Electronic Expansion Valve

- Precision cooling capacity control through Electronic increments to the expansion valve

- Optimising energy conservation by precisley matching the cooling capcity in combination with the Inverter compressor to the heat load

- Wide range of incremental inputs, to optimise the reduction of superheat and improving EER

- Quick incremental positioning responses to feedback to facilitate accurate heat load matching

Condenser – FE2Owlet Axil Fan Technology

- Frequency conversion control, high efficiency and energy saving

- FE2Owlet axil fan, low noise characteristics

- Stainless steel connector and marine grade corrosion-resistant aluminum

- Single/dual refrigeration circuit design, achieve centralized condensation solution